Clear as Mud

Drywall mud, a term commonly used by construction professionals and DIY enthusiasts alike, plays an integral role in the building and finishing of walls in modern homes and commercial spaces. Its purpose extends far beyond simple wall coverage, serving as the foundation for a smooth, finished surface that enhances both the aesthetics and structural integrity of interiors. In this blog post, we’ll dive deep into the history, composition, and purpose of drywall mud, exploring its evolution and importance in contemporary construction.

What Is Drywall Mud?

Drywall mud, also known as joint compound, is a plaster-like material used in the finishing process of drywall installation. It’s applied to seams between drywall panels, filling in gaps, smoothing over joints, and creating a seamless, flawless surface. Once applied, drywall mud helps to make the transitions between drywall sheets virtually invisible, resulting in a uniform, polished finish.

Drywall mud is not only functional but also essential for the final visual appeal of any room. It can be sanded to a smooth texture or left textured, depending on the desired finish. Different types of drywall mud are available, each formulated for specific applications, such as taping, finishing, patching, or texturing.

The History of Drywall Mud

The Rise of Drywall

Before drywall became the go-to material for constructing interior walls, plaster was the material of choice. In the late 19th century, plaster was applied by hand, and the process was both time-consuming and labor-intensive. It required multiple layers and drying times, which contributed to longer construction periods and higher labor costs. The need for a quicker, more cost-effective method led to the creation of drywall, which was introduced in the early 1900s.

Drywall, initially called “gypsum board” or “sheetrock,” quickly became popular due to its ease of installation. Unlike plaster, drywall panels could be pre-manufactured and cut to size, reducing the labor required to create interior walls. The invention of drywall revolutionized the construction industry, offering a much faster way to build walls.

However, the installation of drywall presented its own challenges. Seams between the panels needed to be covered, and the edges of the drywall needed to be concealed to prevent visible joints and imperfections. This is where drywall mud became indispensable.

The Development of Drywall Mud

The history of drywall mud is closely tied to the rise of drywall as a building material. Initially, drywall installers would use a simple mixture of gypsum and water to fill the joints between drywall sheets. Over time, the composition of this mixture evolved as manufacturers began to develop more sophisticated formulas designed for better adhesion, flexibility, and durability.

In the 1940s and 1950s, pre-mixed joint compounds started to emerge, simplifying the installation process and allowing for smoother, more consistent finishes. These compounds were also formulated with additives that improved their workability and drying time. Today, modern drywall mud comes in a range of types, each suited to a specific task, from taping to finishing to texturing.

The Composition of Drywall Mud

Drywall mud is a mixture of several key ingredients that contribute to its workability, adhesion, and finish quality. These components vary depending on the type of mud being used, but generally, drywall mud consists of the following:

1. Gypsum (Calcium Sulfate Dihydrate)

Gypsum is the primary ingredient in drywall mud. It’s a naturally occurring mineral that has been used in construction for thousands of years. Gypsum gives drywall mud its characteristic texture and strength. It is ground into a fine powder, which, when mixed with water, forms a paste-like substance that can be applied to the seams between drywall panels.

2. Water

Water is added to gypsum to create a smooth, spreadable consistency. The amount of water used can vary depending on the desired thickness or smoothness of the mud. Water also helps with the drying process, as it evaporates over time, leaving behind a solid, hardened surface.

3. Binders and Additives

To improve the strength, flexibility, and adhesion of drywall mud, manufacturers incorporate various binders and additives. These can include ingredients such as starch, latex, and cellulose. The goal is to create a mixture that adheres well to drywall surfaces without cracking or shrinking as it dries.

4. Clay and Fillers

Some drywall mud formulations contain clay or other fillers to give the mud added body and smoothness. These fillers also help the mud stay in place when applied to vertical surfaces without sagging or dripping.

5. Antifoaming Agents

Some types of drywall mud contain antifoaming agents to prevent the formation of bubbles while the mud is being mixed. These agents ensure a smoother application and better finish.

6. Drying Agents

To speed up the drying process, certain types of drywall mud include drying agents or accelerants. These help the mud set faster, allowing for quicker application of subsequent layers.

Types of Drywall Mud

While all drywall mud serves the same basic function, different types are designed for specific applications. The main types of drywall mud include:

1. All-Purpose Joint Compound

As the name suggests, all-purpose joint compound is a versatile material that can be used for all stages of drywall installation, from taping to finishing. It is easy to work with and provides a smooth finish. However, it can take longer to dry than some other types of drywall mud, and it may shrink slightly as it sets.

2. Taping Joint Compound

Taping joint compound is formulated specifically for use when attaching drywall tape to seams. It has a thicker consistency that helps to adhere tape to the drywall surface and fill in the joint gaps. It is often used in the first layer of drywall finishing, providing a solid foundation for additional coats.

3. Finishing Joint Compound

Finishing joint compound is a lighter, smoother version of drywall mud, ideal for the final coats of a drywall project. It is designed for use after the taping compound has dried and has been sanded. This type of mud produces a fine finish that is easy to smooth and sand.

4. Setting-Type Joint Compound

Unlike pre-mixed compounds, setting-type joint compound comes in a powder form that must be mixed with water before use. It contains accelerants that cause it to harden quickly, making it ideal for situations where rapid drying is required. This type of mud is often used for patching and repairs.

5. Lightweight Joint Compound

Lightweight joint compound is designed to be easier to handle and apply than regular drywall mud. It is less dense, which makes it easier to spread, and it weighs less, reducing strain on the user. It is often used for finishing applications where a smooth surface is required.

6. Texturing Compound

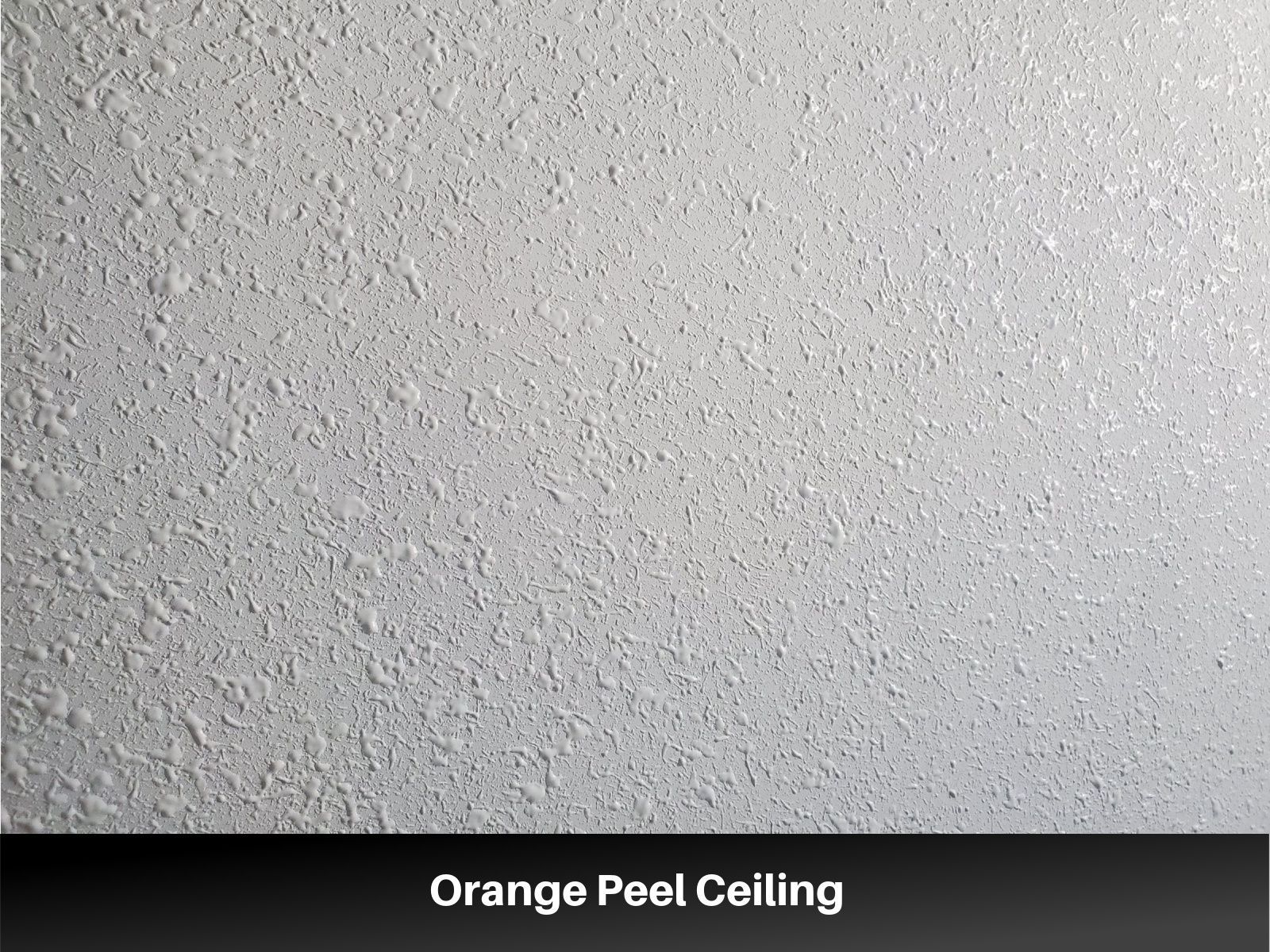

Texturing compound is a thick, textured form of drywall mud that is applied to create different wall and ceiling textures. Common textures include knockdown, orange peel, and popcorn ceilings. This type of mud is formulated to hold its shape as it is applied, allowing for varied patterns and finishes.

The Purpose of Drywall Mud in Modern Homes and Spaces

Drywall mud plays several critical roles in modern construction. It is essential not only for creating a smooth and visually appealing surface but also for providing structural benefits. The following are the primary purposes of drywall mud in homes and commercial spaces:

1. Concealing Seams and Joints

Drywall sheets are typically installed with small gaps between them to allow for expansion and contraction. Drywall mud is used to fill in these gaps, sealing the seams between the panels and covering any screw or nail holes. This helps to create a smooth, continuous surface that is both functional and aesthetically pleasing.

2. Smoothing Surfaces

Drywall mud serves to smooth rough edges, joints, and imperfections on drywall panels. Once the mud is applied and sanded, it results in a flawless surface that can be painted or finished to any desired texture. This process is essential for achieving professional-quality results in interior wall construction.

3. Enhancing Adhesion

The joint compound creates a solid bond between the drywall panels, preventing them from shifting or separating over time. This improves the structural integrity of the wall and reduces the risk of cracks and gaps forming as the building settles.

4. Improving Fire Resistance

Gypsum, the primary ingredient in drywall mud, is a naturally fire-resistant material. When applied to drywall seams, the compound helps to improve the overall fire resistance of the walls. This provides an additional layer of safety in modern buildings, which is especially important in residential and commercial spaces.

5. Noise Reduction

Drywall mud contributes to soundproofing by sealing gaps and seams in the drywall. The smoother and more tightly sealed the drywall is, the less likely sound will travel through the walls. This makes drywall mud an essential component in creating quieter, more private spaces.

6. Aesthetic Finish

Finally, drywall mud plays a major role in the aesthetics of a room. Whether it’s a sleek, smooth finish or a textured wall, drywall mud allows for a variety of design choices. It can be sanded, painted, or textured, enabling homeowners and designers to create the perfect ambiance in any room.

Conclusion:

Drywall mud has a rich history that parallels the evolution of modern construction techniques. From its humble beginnings as a simple mixture of gypsum and water to the sophisticated formulations used today, drywall mud has become an essential material in the construction and finishing of walls in modern homes and commercial buildings.

The composition of drywall mud, which includes gypsum, water, binders, and additives, contributes to its effectiveness in creating smooth, durable, and visually appealing surfaces. Whether it’s used to conceal seams, enhance adhesion, or create textured finishes, drywall mud plays a vital role in the construction process.

As technology continues to advance, drywall mud and its applications will continue to evolve, providing even greater flexibility and functionality for builders, designers, and homeowners alike. Its significance in modern construction cannot be overstated, as it is an integral part of creating the finished, polished interiors we rely on in our daily lives.